metrology

Metrology is “the science of measurement”

A metrology engineer, or metrologist, specializes in science or engineering-related measurements. Their duties may include calibrating instruments, designing new tools or systems of measurement, interpreting data, or researching the science of measuring.

There are seven basic tools a metrologist will use in a modern CNC machine shop environment:

- Surface plate, which is a flat surface used as a reference point for vertical (Y-axis) measurements

- Go/no-go gage

- Callipers

- Micrometer

- Air gage

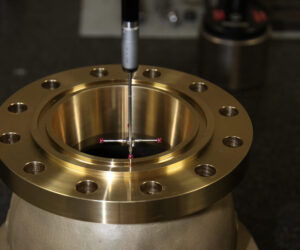

- Coordinate Measuring Machine (CMM)

- Laser scanning arms

VEEM Metrologists and quality control

VEEM metrologists use Laser scanning using geometric software. Computer controller Coordinate Measuring Machines and other advanced tools to develop and evaluate manufactured components dimensionally and to measure characteristics and enable the user to identify and minimize the magnitude of error sources contributing to the uncertainty of results. This ensures that the measurement process is reliable, accurate, and consistent, and meets the necessary quality control requirements. All measurements are referenced back to the Australian standard of lengths.

Metrology and Calibration services offered.

Through participation in government and industrial standardisation committees and professional societies, we advise others on methods of resolving measurement problems and exchange information with other metrology personnel.

VEEM undertakes calibration and testing services both in-house and on-site. Providing full traceability, calibration of mechanical measuring instruments is undertaken in accordance with the requirements of all national and international inspection and surveying authorities.

Metrology equipment is calibrated in accordance with relevant Australian standards. Ideal for ISO 9002 companies.

Capabilities

- Laser scanning up to 0.008mm accuracy for an envelope up to 10m3

- CMM dimensional measurement for components up to 2000 x 1000 x 1000 mm

- Hardness testing

- Thread gauging

- Surface roughness probing

- Coating thickness gauging using magnetics

- Section thickness gauging using ultrasonics

- Coordinate measuring

- Calibration of measuring instruments

- Gauging

- Mechanical Testing

- Statistical Analysis