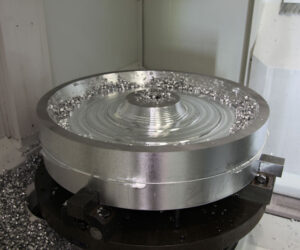

Fully equiped machine shop with high quality 5-axis CNC machining up to 4.2m in diameter, advanced milling facilities and integrated CAD/CAM systems.

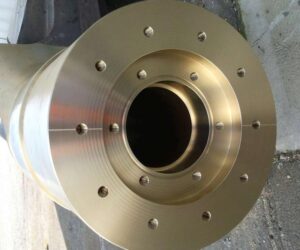

VEEM has, since 1968, maintained a reputation for high precision and quality in manual and CNC machining in a variety of fields such as Aerospace, Marine, Mining, and Oil and Gas.

With turning capacity of 4.2m in diameter on our largest CNC machine, the largest jobs can be easily accommodated in our Western Australian facilities. Along with larger milling facilities no job is too big or too small for our fully equipped machine shop.

Manufacturing of specialized components for aerospace, oil and gas, and defence industries requires strict adherence to a wide variety of standards and guarantees of dimensional accuracy. At VEEM we can provide full documentation of all features normally not possible with conventional equipment. This ensures the real cost of the products to our clients are lower.

Sophisticated CAD/CAM systems are directly linked to all CNC machines to enable rapid programming and downloading of data. This allows economical production of relatively small quantities and, in some cases, single items can be cost effectively produced.

Capabilities

- CNC turning (diameters to 4.1m)

- CNC Milling (lengths to 3750mm, weight 25 tonnes, 5 axis)

- Manual turning (diameters to 4.1m)

- Manual milling (lengths to 3750mm, weight 25 tonnes)

- Surface, cylindrical and circumferential grinding equipment

- CMM Co-ordinate Measuring Machine

- Precision Measuring Instruments

- CAD/CAM Facilities

- Calibration, precision measuring and gauging

- Slotting